Cold heading is one of those manufacturing terms that many people hear frequently—especially in fastener production—but few truly understand at the beginning. When I first entered this industry years ago, I quickly realized that misunderstandings about cold heading often lead to poor equipment choices and unrealistic production expectations.

If you are new to cold heading or considering investing in a cold heading machine, this guide will help you build a solid foundation before making any decisions.

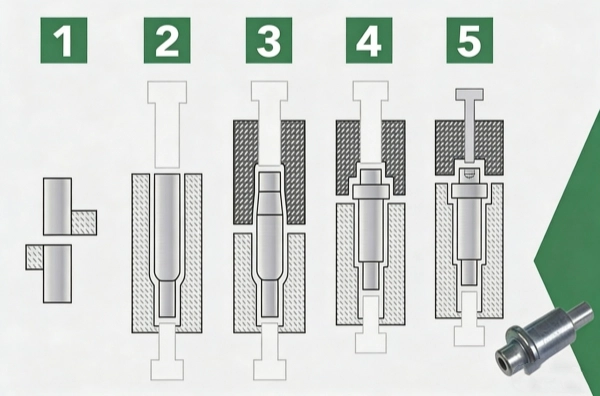

Cold heading is a metal forming process in which wire or rod material is shaped into a specific geometry at room temperature, using high-pressure deformation rather than heat. The process relies on dies and punches to force metal to flow plastically into the desired shape.

Unlike machining, cold heading does not remove material. Instead, it redistributes the metal, which is why cold headed parts often have higher strength, better grain flow, and excellent dimensional consistency. In my experience, this is one of the biggest advantages beginners tend to underestimate.

Cold heading machines typically operate at high speeds and are designed for mass production. Once properly set up, they can produce thousands—or even millions—of identical parts with minimal variation. This makes cold heading a core technology in industries where consistency, strength, and efficiency matter.

One of the most common beginner questions I hear is: “How is cold heading different from forging or machining?” The differences are fundamental.

Compared with hot forging, cold heading:

• Requires no heating, reducing energy consumption

• Preserves tighter dimensional tolerances

• Improves surface finish without secondary processing

Compared with machining, cold heading:

• Generates almost no material waste

• Achieves higher production efficiency

• Produces stronger parts due to continuous grain flow

There is also cold forging, which is often confused with cold heading. From a practical standpoint, cold heading is a specialized form of cold forging, optimized for axial forming and high-speed production—particularly for fasteners and similar components.

Understanding these distinctions is essential before selecting a manufacturing method or investing in equipment. Cold heading is not always the right solution, but when applied correctly, it is often the most economical and reliable one.

Cold heading machines are most commonly associated with fasteners, and for good reason. Over the years, I have seen cold heading used successfully to produce:

• Bolts, screws, and nuts

• Rivets and pins

• Studs and shafts

• Automotive fasteners and special connectors

• Electrical and mechanical components requiring high strength

Cold heading is particularly well suited for axisymmetric parts and components with heads, flanges, or multiple forming steps. With multi-station cold heading machines, even relatively complex geometries can be achieved without machining.

If your products require high strength, consistent dimensions, and large production volumes, cold heading is often the most competitive manufacturing solution available.

Choosing between a single-station and a multi-station cold heading machine is one of the most important decisions for beginners.

Single-station cold heading machines:

• Simpler structure and lower initial investment

• Suitable for basic shapes and smaller production volumes

• Easier for beginners to operate and maintain

Multi-station cold heading machines:

• Perform multiple forming operations in one cycle

• Ideal for complex fasteners and high-volume production

• Higher efficiency but greater setup and tooling complexity

From my experience, many new buyers focus too much on speed and overlook process suitability. A multi-station cold heading machine is powerful, but only when the product design and production volume justify it. Otherwise, a well-selected single-station machine may deliver better long-term returns.

Before investing in a cold heading machine, there are several critical points I always advise newcomers to consider:

Machine selection should always start with your product drawings, material type, and tolerance requirements—not the other way around.

Different materials behave differently under cold heading. Understanding material flow and deformation limits is essential for stable production.

Even the best cold heading machine cannot compensate for poor dies and punches. Tooling precision directly affects product quality and machine life.

Consider not only current orders but also potential future product upgrades or higher volumes.

For beginners, especially, technical support, commissioning assistance, and training are just as important as machine specifications.